Acquisition Opportunity – Studio Kosnik™ Intellectual Property Portfolio

Dear [Investor/Partner/Collector],

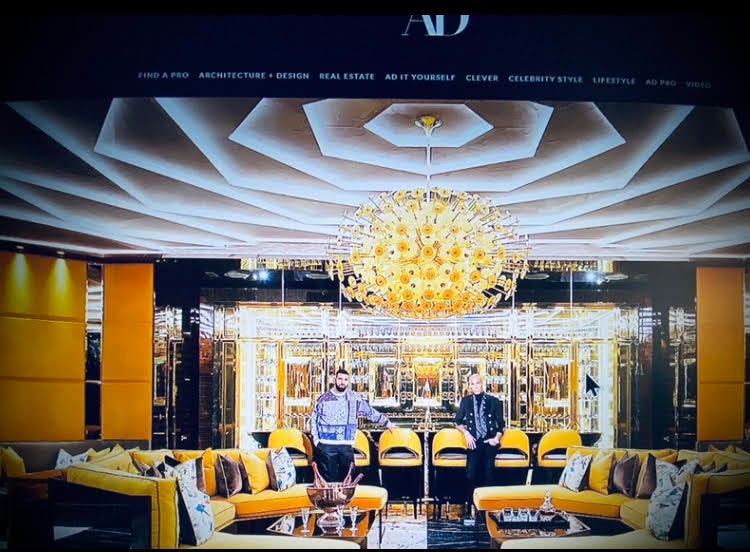

My name is Karol Kosnik, founder of Studio Kosnik™, an internationally recognized design platform at the intersection of IKEA hacking, interior systems, and DIY culture. Over the last decade, I have built a unique intellectual property portfolio spanning design philosophy, cultural commentary, and experimental applications of AI in interiors.

I am offering the entire Studio Kosnik™ intellectual property package for acquisition.

Included Assets:

-

Registered & Claimed Trademarks: StudioKosnik™, Swedish Socialism™, WILLIAM™

-

Digital Influence Portfolio: “Digital Mountains” — over a decade of press coverage, installations, product launches, and cultural impact (TO DO Design Festival, viral projects, etc.)

-

StudioKosnik AI™ [infinity]: An AI-enhanced design tool trained on IKEA systems, optimization theory, and DIY hacking frameworks

-

Studio Blog & Archives: Articles, show records, design blueprints, IKEA hacks, process documentation

-

4-Month Transition Training: A direct knowledge transfer process where I train your team in the philosophy, systems thinking, brand positioning, and AI integration that powers Studio Kosnik

This is not just an IP transfer. It’s a cultural asset handoff — the transfer of authority and authorship over one of the most disruptive voices in IKEA hacking and high-resolution interiors.

I am open to negotiations, partnership models, and licensing if the mission aligns.

For a full prospectus or to begin discussions, please contact me at Karol.Kosnik@gmail.com

Warm regards,

Karol Kosnik

Founder, Studio Kosnik™

.jpg)